The Future of Artificial Intelligence in Manufacturing: A Deep Dive into STTA406

Introduction:\

The advent of artificial intelligence (AI) has brought about significant transformations in various industries, including manufacturing. One of the key developments in this field is the STTA406 framework, which has gained attention for its potential to revolutionize manufacturing processes. In this blog post, we will delve into the STTA406 framework, explore its applications, and discuss its implications for the future of AI in manufacturing.

1. What is STTA406?\

The STTA406 framework, short for Smart Technology Tool for Analytics in 406, is a cutting-edge AI solution designed specifically for the manufacturing industry. It leverages advanced machine learning algorithms, big data analytics, and IoT connectivity to enable real-time monitoring, predictive maintenance, and optimization of manufacturing operations.

2. Enhancing Efficiency through Real-time Monitoring:\

One of the key benefits of the STTA406 framework is its ability to provide real-time monitoring of manufacturing processes. By leveraging sensor data, AI algorithms can detect potential issues or anomalies in production lines, allowing manufacturers to take proactive measures to resolve them. This not only reduces downtime but also improves overall operational efficiency.

3. Predictive Maintenance for Increased Reliability:\

Another crucial aspect of the STTA406 framework is its incorporation of predictive maintenance capabilities. By analyzing historical data and utilizing machine learning algorithms, manufacturers can proactively identify equipment failures or breakdowns before they occur. This helps prevent costly downtime and enables more efficient planning of maintenance activities.

4. Optimizing Production through Data Analytics:\

The STTA406 framework also empowers manufacturers to optimize their production processes by harnessing the power of data analytics. By gathering and analyzing vast amounts of data from various sources, such as production lines, supply chain systems, and customer feedback, AI algorithms can identify patterns, bottlenecks, and opportunities for improvement. This enables manufacturers to make data-driven decisions that enhance productivity and yield better quality products.

5. Redefining Human-Machine Collaboration:\

While AI and automation have often been associated with workforce reduction, the STTA406 framework takes a different approach. It aims to redefine human-machine collaboration by leveraging AI capabilities to augment human skills and expertise. With AI handling repetitive and monotonous tasks, human workers can focus on more complex and creative aspects of production, leading to higher job satisfaction and productivity.

6. Challenges and Considerations:\

Although the STTA406 framework holds immense potential, there are challenges and considerations that need to be addressed. These include data privacy and security concerns, the need for skilled AI professionals to implement and maintain the framework, and the potential impact on traditional job roles. Manufacturers must carefully navigate these challenges to ensure a successful integration of the STTA406 framework.

7. The Future of AI in Manufacturing:\

As the STTA406 framework gains wider adoption, it presents a glimpse into the future of AI in manufacturing. With advancements in AI and machine learning, we can expect even more sophisticated and intelligent solutions that further optimize production, improve product quality, and enhance overall operational efficiency. The integration of AI into manufacturing processes will become increasingly seamless, leading to a paradigm shift in the industry.

In conclusion, the STTA406 framework represents a significant step towards the future of AI in manufacturing. By enabling real-time monitoring, predictive maintenance, optimization of production processes, and redefining human-machine collaboration, this framework has the potential to revolutionize the way manufacturers operate. However, it is crucial to address challenges and considerations to ensure a successful implementation. As AI continues to evolve, we can expect further advancements that will reshape the manufacturing landscape, making it more efficient, productive, and sustainable.

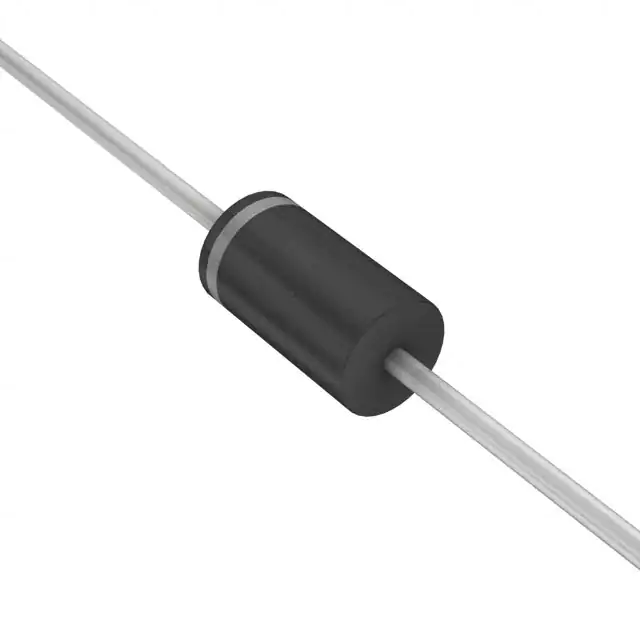

STTA406

- Part Number :

- STTA406

- Manufacturer :

- STMicroelectronics

- Description :

- DIODE GEN PURP 600V 4A DO201AD

- Datasheet :

-

STTA406.pdf

STTA406.pdf

- Unit Price :

- Request a Quote

- In Stock :

- 2015

- Lead Time :

- To be Confirmed

- Quick Inquiry :

- - + Add To Cart

Request a Quote

STTA406 Specifications

- Packaging:

- Tape & Box (TB)

- Series:

- TURBOSWITCH™

- RoHS:

- RoHS

- Speed:

- Fast Recovery =< 500ns, > 200mA (Io)

- Diode Type:

- Standard

- Part Status:

- Obsolete

- Mounting Type:

- Through Hole

- Package / Case:

- -

- Capacitance @ Vr, F:

- 55 ns

- Supplier Device Package:

- 50 µA @ 600 V

- Reverse Recovery Time (trr):

- 600 V

- Current - Reverse Leakage @ Vr:

- 4A (DC)

- Voltage - DC Reverse (Vr) (Max):

- 125°C (Max)

- Current - Average Rectified (Io):

- 1.75 V @ 4 A

- Operating Temperature - Junction:

- Voltage - Forward (Vf) (Max) @ If:

STTA406 Guarantees

-

Service Guarantees

We guarantee 100% customer satisfaction.

Our experienced sales team and tech support team back our services to satisfy all our customers.

-

Quality Guarantees

We provide 90 days warranty.

If the items you received were not in perfect quality, we would be responsible for your refund or replacement, but the items must be returned in their original condition.

Certified Quality

View the Certificates

View the Certificates